In nearly every industrial setting, from a bustling chemical plant to a serene wastewater treatment facility, there's a constant, unseen force moving fluids. That force is the centrifugal pump, the most common and versatile pump in the world. As a manufacturer with decades of experience, we're here to provide a detailed guide on these essential machines.

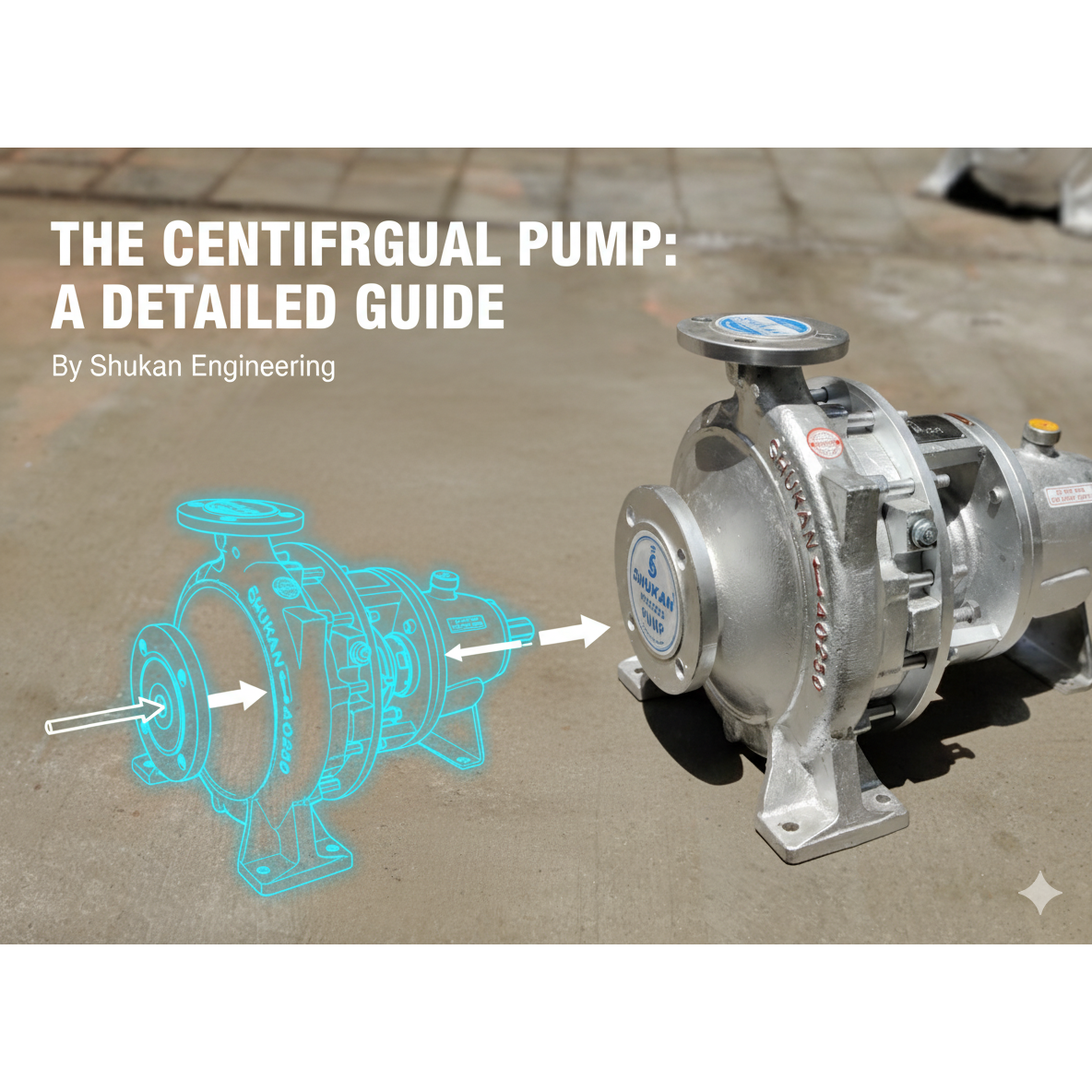

What is a Centrifugal Pump and How Does It Work?

A centrifugal pump is a mechanical device that uses a rotating impeller to move fluid by converting rotational kinetic energy into the hydrodynamic energy of the fluid flow. Its design is based on the simple principle of centrifugal force.

Here’s a step-by-step breakdown:

Fluid Entry: Fluid enters the pump through the suction nozzle at the center of the impeller.

Rotation: The impeller, which is a set of curved vanes, rotates rapidly, imparting kinetic energy to the fluid.

Fluid Exit: As the fluid is flung outward by centrifugal force, it gains speed and pressure.

Pressure Conversion: The fluid then enters the pump casing (or volute), which is a spiral-shaped channel. The casing slows the fluid down, converting its high velocity into high pressure before it exits through the discharge port.

This simple yet powerful mechanism allows centrifugal pumps to deliver fluids at high flow rates, making them a preferred choice for countless applications.

Key Types of Centrifugal Pumps

Centrifugal pumps can be classified in several ways, often based on their design or how they handle fluid.

By Number of Impellers:

Single-Stage: Uses one impeller. It's the most common type, ideal for high-flow, low-to-moderate-head applications.

Multi-Stage: Uses two or more impellers connected in series. Each impeller boosts the fluid's pressure, making these pumps perfect for high-head applications.

By Casing Design:

End Suction: The fluid enters from the end of the casing, and the discharge is at the top. This is the most common and simple design.

Split Case: The casing is split, allowing for easy access to internal components without disturbing the piping. Ideal for large flow rates.

By Impeller Type:

Open: Used for fluids with solids, like slurries or wastewater, as they are less prone to clogging.

Semi-Open: A balance between open and closed, offering better efficiency while still handling some solids.

Closed: The most efficient type, used for clean liquids.

Advantages and Ideal Applications

Centrifugal pumps are the workhorses of the industry for several reasons:

Simplicity & Reliability: They have few moving parts, leading to less friction, lower maintenance, and a longer lifespan.

High Flow Rate: They are designed to move large volumes of fluid efficiently, making them ideal for fluid transfer applications.

Versatility: With a wide range of materials and designs, they can be customized for almost any fluid, from thin liquids like water to corrosive chemicals and even abrasive slurries.

You'll find them powering systems in:

Chemical Manufacturing

Oil & Gas

Water & Wastewater Treatment

Mining

Agriculture

How to Choose the Right Centrifugal Pump

Selecting the correct pump is a critical decision. Here’s a checklist of key factors to consider:

Fluid Properties: Is the liquid clean, corrosive, abrasive, or viscous? The answer will determine the necessary materials (e.g., SS 316 for corrosive fluids, high-chrome for abrasives).

Flow Rate (Capacity): How much fluid do you need to move per minute?

Head (Pressure): How high or far do you need to pump the fluid?

Temperature: Does the fluid get hot? This is crucial for selecting a thermic fluid pump with proper heat dissipation.

NPSH (Net Positive Suction Head): A critical factor to prevent cavitation, which can severely damage the pump.

Conclusion

Centrifugal pumps are a cornerstone of modern industrial operations, valued for their reliability, efficiency, and adaptability. By understanding their basic principles and selecting the right model for your specific needs, you can ensure a smooth and continuous flow for years to come.

Need an expert opinion? Contact Shukan Engineering for a customized solution tailored to your application.

Keywords

Centrifugal pump maintenance tips

Centrifugal pump selection criteria

Multi-stage centrifugal pump advantages

Centrifugal pump material selection

Chemical and wastewater centrifugal pumps

High flow rate centrifugal pumps

Industrial centrifugal pump applications

Centrifugal pump with impeller design

Types of centrifugal pumps

Centrifugal pump working principle